IMAGEN DE REFERENCIA

- Sobre pedido

Existen artículos en su cotización.

Precios totales :

Di algo..

Sin resultados, re intente de nuevo

Navegador incompatible

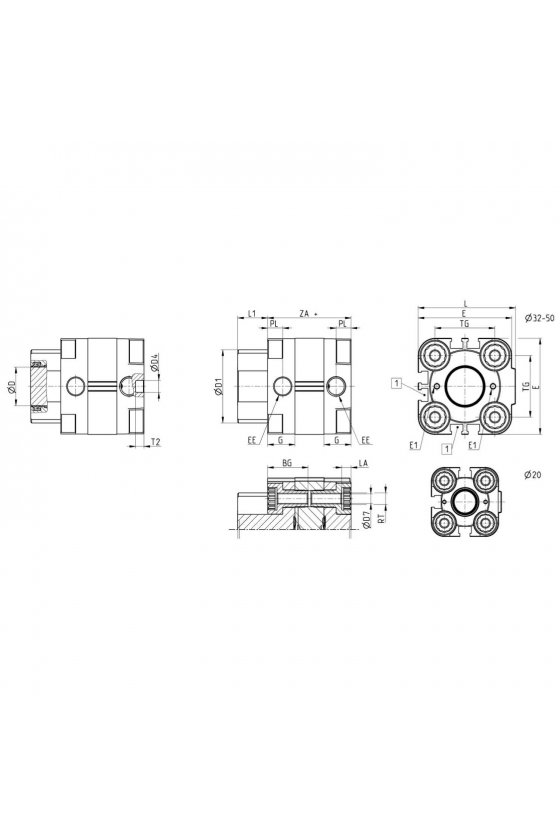

CILINDRO STOPPER UNITOP D.E. D=20, C=15

¿Necesitas certificado de calibración?, ¡pregunta a tu vendedor favorito vía WhatsApp!

| Ø | BG | G | ØD | ØD1 | ØD4 | ØD7 | E | EE | E1 | L | LA | L1 | PL | RT | T2 | TG | ZA | ZB |

| 20 | 18.5 | 12 | 12 | 26 | 6 | 4 | 35.5 | G1/8 | M2 | 38 | 5 | 11.5 | 8 | M5 | 4.5 | 22 | 38 | 49.5 |

| Construction Cylinder design Operation Sizes Strokes (min - max) Rod versions Non-rotating function | profile with self-tapping screws compact based on UNITOP and ISO 21287 standards double-acting, single-acting rear spring, double-acting rear spring 20, 32, 40 (Mod. ST32 only), 50 mm 5 ÷ 30 mm (see the table of standard strokes) without thread, with female thread, non-rotating, non-rotating with feemale thread, non-rotating with roller with technopolymer anti-friction ring |

| Fixing and mounting Type of cushioning | direct with holes on the end-caps, in any position mechanical end-stroke shock absorbers in rubber |

| Max frequency Working temperature Storage temperature Working pressure Max rotation play Max torque (for non-rotating version) | 5 Hz (Ø 20, 32, 40 mm) - 3 Hz (Ø 50 mm) 0°C ÷ 80°C (with dry air -20°C) -20°C ÷ 100°C 1 ÷ 10 bar (double-acting) - 2 ÷ 10 bar (single-acting) ± 4° (Ø 20, 32 e 40 mm) - ± 3° (Ø 50 mm) 1.5 Nm (Ø 20 mm) - 2.5 Nm (Ø 32 e 40 mm) - 3.5 Nm (Ø 50 mm) |

| Medium Lubrication | filtered air in class 7.8.4 according to ISO 8573-1 standard. Not required. The cylinder is pre-lubricated. If lubricated air is used, it is recommended to use oil ISOVG32. Once applied the lubrication should never be interrupted. |

| Use with external sensors | slots on the three sides for proximity switches Mod. CST and CSH |

Envíanos un WhatsApp

Contacto vía: